Powering the Future with Solid Oxide Innovation

A solid oxide electrolyser is a high-temperature device that splits water into hydrogen and oxygen using electricity. Operating at temperatures between 600–800°C, SOEs are highly efficient and can also utilize CO₂ to produce syngas for synthetic fuels.

Solid oxide electrolysis involves the use of solid oxide electrolytes, typically ceramic materials, in the electrolysis process to produce hydrogen. The key distinction is the high operating temperatures, typically in the range of 600-800 degrees Celsius.

HIGH EFFICIENCY

The SOEC has a very high efficiency compared to the other 2 technologies. It requires around 37 KWh to produce per kg of hydrogen compared to 55 KWh for the other technologies.

REVERSIBLE MODE

The SOEC is a reversible process where the splitting of water gives oxygen and hydrogen separately and when the hydrogen and oxygen is supplied it gives electricity which is not possible with the other technologies.

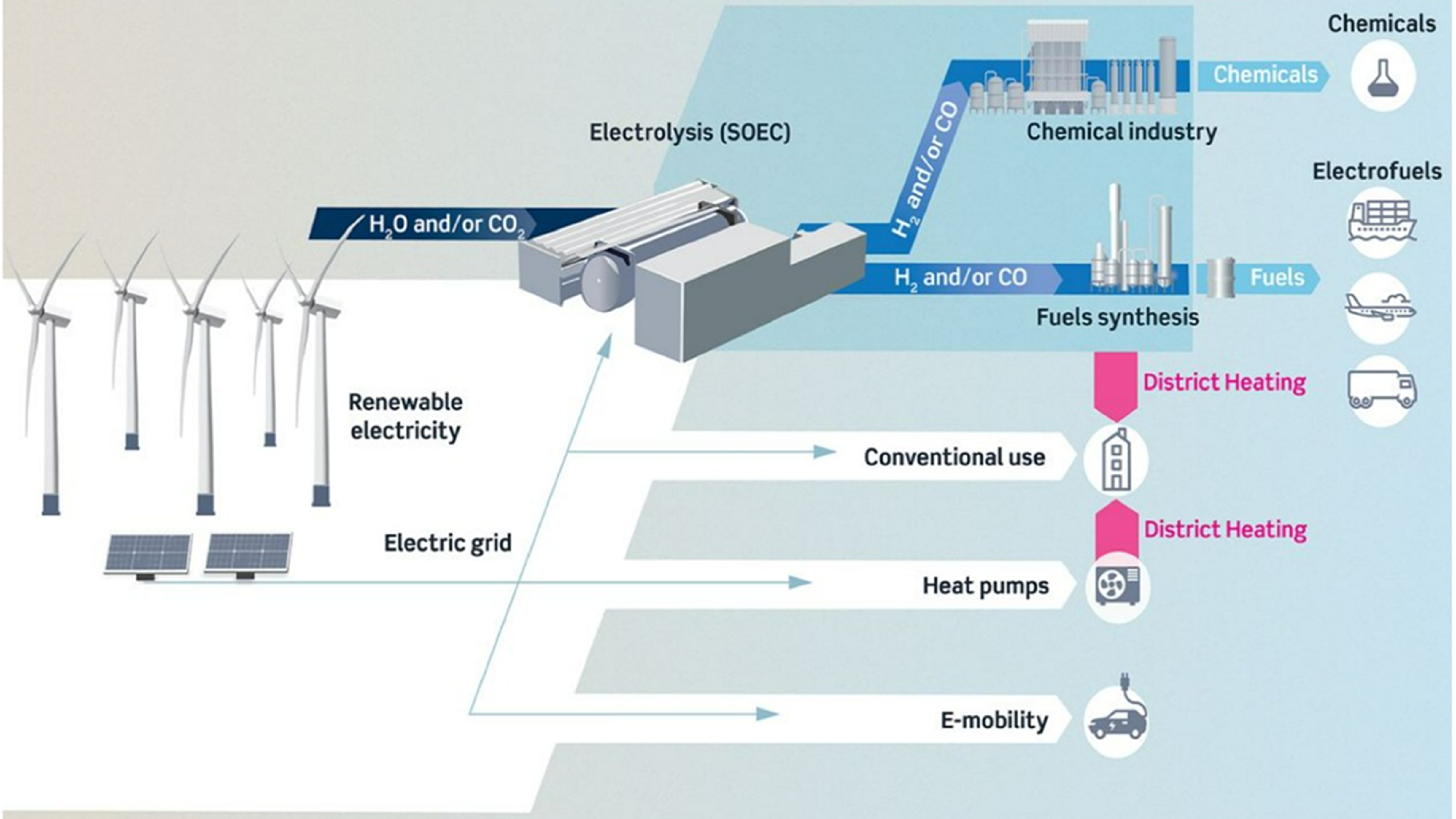

INTEGRATION WITH RENEWABLES

The main drawback of any electrolysis process is the limited availability of continuous current flow from renewables where SOEC can be combined with heat and electricity (Mainly heat) and supported well by renewables.

INDUSTRY COMPATIBILITY

Since it runs on heat majorly it can be combined with the waste heat available in the industries to reduce the Levelized cost of hydrogen produced.

RAW MATERIAL AVAILABILITY

Other two technologies need noble metals and expensive metals like Pt, Pd which are not easily available in our country whereas this technology requires robust solid oxide materials which are easy to be procured and also cheap compared to the others.

SCALING

The estimated learning rate for the SOEC technology is almost double than that of the other two technologies. Since it has a better learning rate it is much suited for large scaled production to meet the high demand and can be more suited to the industry needs.

FUEL FLEXIBILITY

This technology allows the usage of various fuels like Methanol.

SOEC technology can provide green hydrogen as a clean reducing agent, replacing coke in blast furnaces and enabling low-carbon or carbon-neutral steel production.

SOEC-produced hydrogen can serve as a reliable fuel source for these zero-emission rail transport solutions.

SOEC-based hydrogen can be used to replace fossil fuels in kilns, lowering carbon emissions while maintaining high-temperature process efficiency.

SOEC technology facilitates efficient hydrogen production, helping automakers develop cleaner, more sustainable transport solutions with longer range and faster refueling times.

Subscribe to our Newsletter